The company independently completes the plastic mold CNC, injection molding, circuit board deign, component PCBA, laser radium engraving, ultrasonic welding, kinds of power cord and terminal manufacturing, integrated manufacturing chain, product test and other complete fine manufacturing processes, Has a fully automated internal structure assembly line. The whole process of automatic production and assembly greatly improve the production efficiency, saving labor costs. There are 6 processing and assembly lines, and the daily production capacity of finished products can reach 50.000 units.

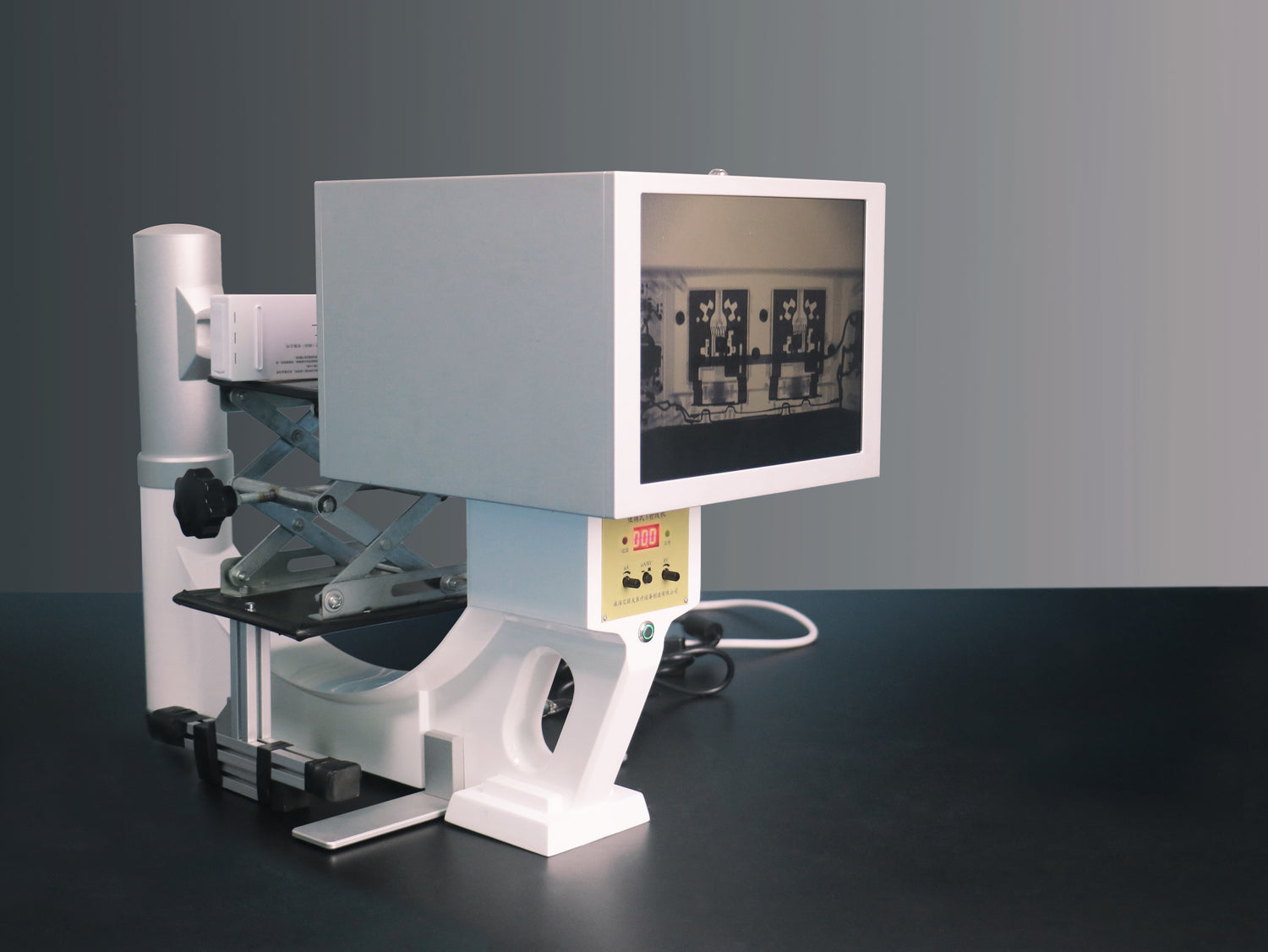

It has all the equipment required for the production workshop, including plug comprehensive tester, silent terminal machine, laser engraving machine, power cord winding machine, terminal welding machine, plug making machine, etc. Relying on the world's first "mechanical trigger" structure, the company redefines traditional sockets with safe and secure electricity as the core demand, creates various types of sockets and electrical products that are waterproof, anti-electric shock and anti-short circuit, and further realizes a breakthrough in safe electricity consumption, and is a revolutionary of traditional sockets.